The "lost wax" brass process is an ancient tecnique used for making brass models and sculptures. Amongst the Asante of Ghana this technique was used to mend the bones of ancestors which are considered sacred. It was also used to make the gold ornaments so beloved in West Africa. Nowadays brass is more commonly used... First a detailed model object is made completey out of bees wax. This wax mould is then hardened with ash and prepared for the kiln where recycled brass is melted and replaces the wax - which is "lost". See how it's done below.

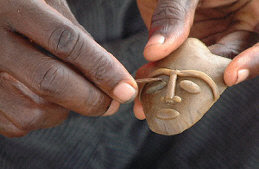

Making the wax model

Wax from the African honey bee is used

First it's formed into the rough shape and size needed

Sometimes the wax is pressed into moulds to form the basic shape

After the basic shape has been formed...

Pieces of wax are modelled to make the decorations

Then the decoration can begin

An old syringe is used to make strings of wax

But when you need a lot production can be cranked up using innovative technology!

This is fiddly work - the fine strings of wax are shaped and fused to the base shape - it needs a steady hand and great concentration...

After the strings of wax have been applied they are sculpted - every detail made in wax will be replaced by brass

The finished wax faces - Adinkra symbol "gye nyame" moulds

Beads and hollow brass models are made from fine strings of wax built up over a charcoal mould

All done with these simple tools...

And all part of a day's work for this artisan at his workbench

Building up the wax model into a mould

Pieces of charcoal are pounded...

Into a fine powder

The powder charcoal is mixed with water...

And the wax models are dipped into the mixture

And given a thick coating...

And then left to dry and harden

Channels are left for the brass to pour in and replace the wax

Preparing the moulds for the kiln

The models are dipped again and again to build up the mould cases

As the moulds build up fibrous material is added to the mixture to strengthen it

The Kiln

Crucibles are made that exactly fit over the finished the finished moulds

How it works is that you put the brass in here...

And it fits on top like this

Brass taps and pipes are often used

Along with brass models that didn't work out

The crucibles are all filled with brass and then joined together to the waiting mould

A trench kiln is prepared and the crucibles are put in the kiln and fired. As they get hot the wax melts and the molten brass flows in and takes its place

Cleaning and finishing

After they have baked in the kiln the crucibles are broken open to reveal the finished pieces inside

But it's not over yet... each of the pieces has to be cleaned which is a long job

Everyone in the workshop helps out - even the children

In fact it's a family job... and this is how children start to learn the skill

This man is working on an X rated model.... something for everyone!

And here are the glorious finished pieces - all cleaned and shiny

People come from all over the world to see the skills of these artisans...

And we say good by to the artisans at the "lost wax" brass workshop in Ghana

Thursday, December 1, 2011

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment